SEVENOAKS

TONBRIDGE

TUNBRIDGE WELLS

ORPINGTON

BROMLEY

DARTFORD

01732 617161

BUILDING SUPPLIES LTD

01689 869090

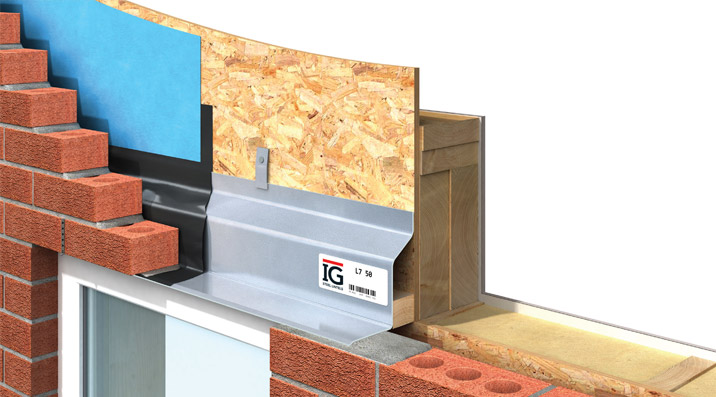

Timber Frame Lintels

Material

Timber Frame lintels are manufactured from pre-galvanised mild steel BS EN 10346:2009 DX51D plus Z600 or grade Z275 to BS5977: part 2, 1983 (BS EN 845-2:2003). There is a minimum zinc coating of 600g/m² galvanising including both sides.

If stainless steel lintels are required:

IG utilise stainless steel grade 304 2b to BS EN 10088- part 2 Astm 240 (European Grade 1.4307).

Heavy Duty Timber lintels are insulated with expanded polystyrene and conform to BS 13163:2008.

Specification

Technical Information details all the specification clauses required for IG lintels. The Specification Clause required for Box lintels is titled “Timber Frame Lintels”.

Designed for use in timber frame construction, the L7 lintels provide support to the outer leaf to brickwork over openings.

To achieve the loading tables shown the L7 lintels must be secured with restraining clips and a timber batten (not supplied) must be used t prevent lateral deflecton (twist) during the building stage.

Installation

Installation of IG’s L7, L7/HD and L7/XHD are all similar.

All Timber frame lintels must be installed with restraining clips and a timber pinch batten to prevent rotation of the lintel during the building stage. Propping may be used to facilitate speed of construction.

To achieve the loading figures shown, the L7 lintel must be secured with restraining clips and a timber pinch batten (not supplied) must be used to prevent lateral deflection (rotation) during the building stage. A single timber pinch batten 300mm long at mid span will be sufficient.

IG timber frame restraint clips are supplied free of charge and must be fixed to the timber frame structure by 3.3mm x 50mm galvanised nails. Allowance should be made for the movement of the timber frame structure due to settlement and shrinkage. Lateral restraint clip should be placed at 500mm centres each side of mid span.

Timber Frame Lintels

L7 L7/HD L7/XHD

Blockwork built tight against inner face of the lintel. Place mortar bed on top of blockwork before floor units are laid to provide even distribution of load. Lintels may be propped to facilitate speed of construction.